Dewater SP

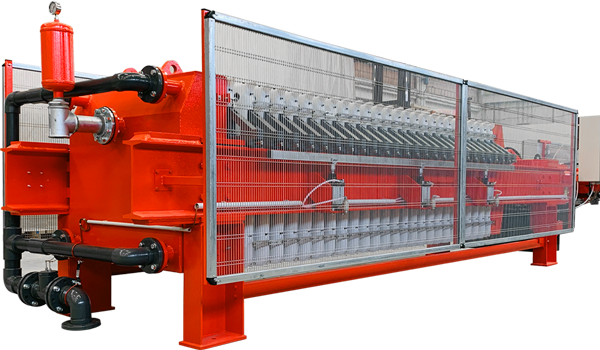

Automatic Filter Press

Features of Dewater SP

Filter Press Model

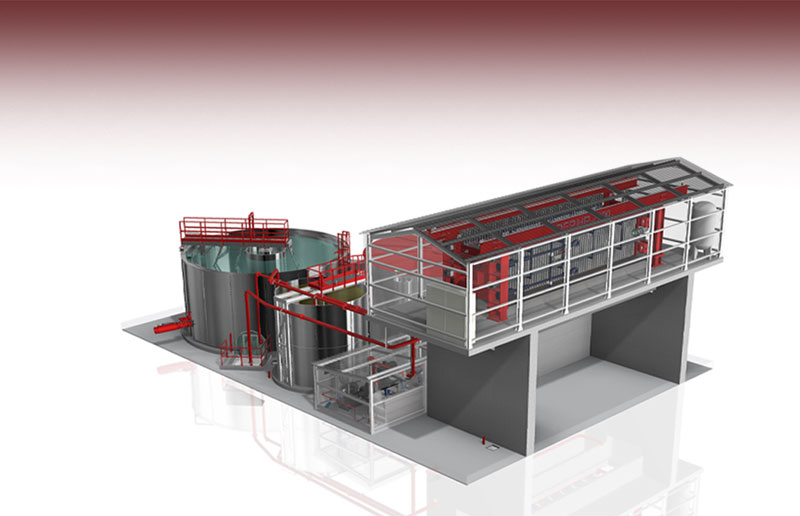

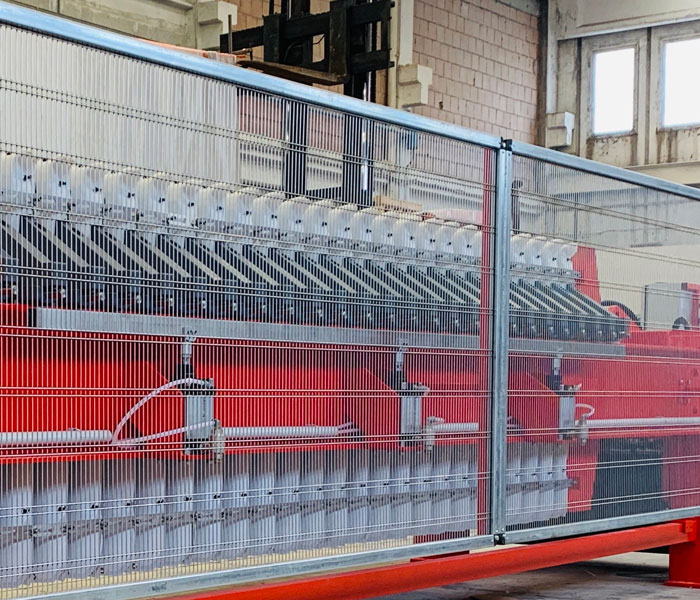

Automatic Filter Presses for medium to high capacity applications

The Dewater SP is an automatic FAST Filter Press made for diverse industrial applications. The filter press delivers efficient & high filtration performance for filtration applications in sectors such as Mining, Metallurgical, Chemical, Petrochemical & all other general industrial waste water treatments.

The filters are highly flexible to be customised according to the specific process & filtration performance requirement of the customer. The operation is fully automatic with simultaneous plate pack opening & automatic cake discharge. This enables to achieve shorter cycle time with high availability.

Main Advantages

Side Beam Design

Fully Automatic Operation

Automatic Cloth Washing

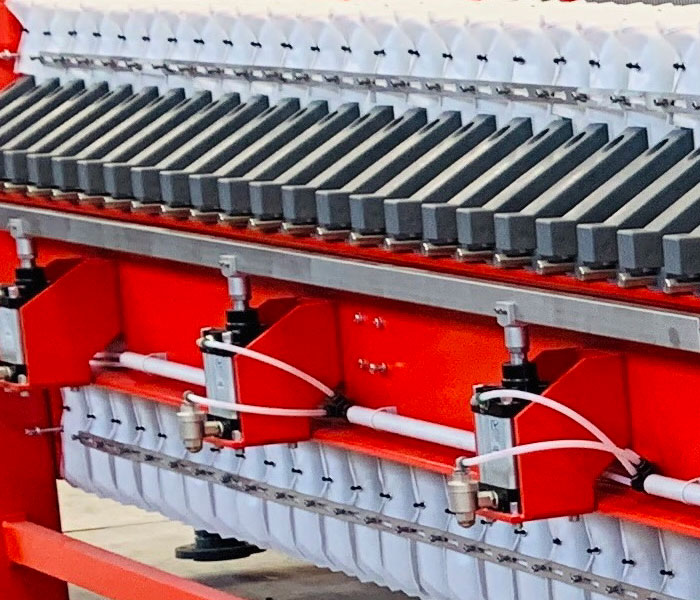

Membrane, Chamber, or Mixed Plate Pack

Advanced Degree of Automation

Simultaneous Opening and Discharge

Low Operational Expenses

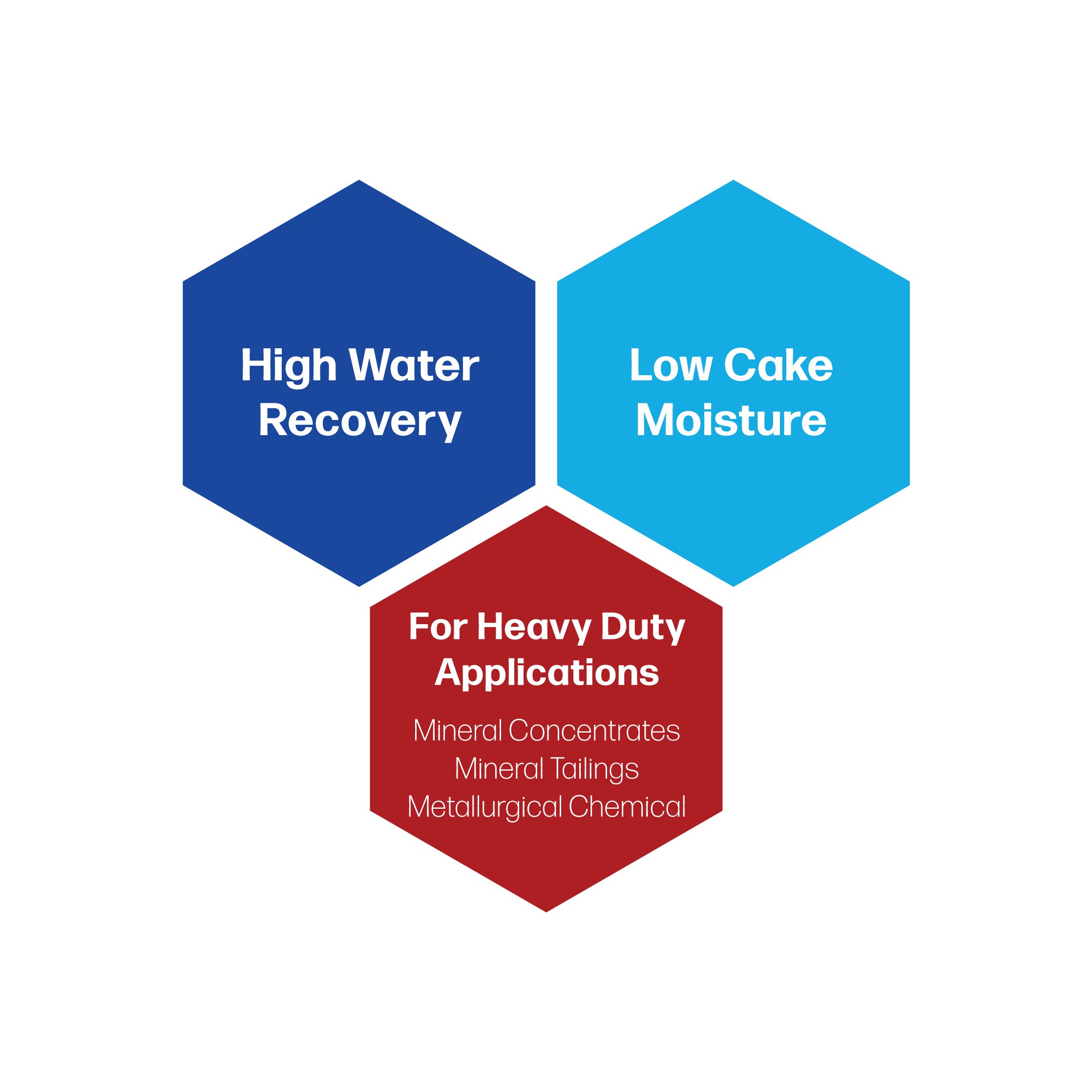

Performance

The Dewater SP is an automatic Filter Press made for diverse industrial applications. The filter press is delivering efficient & fast filtration performance in filtration applications in sectors such as Mining, Metallurgical, Chemical, Petrochemical & all other general industrial & municipal waste water treatments.

Design

Dewater SP model filter presses are designed with dual side beams. The filter presses are highly flexible to be customised according to the specific process & filtration performance requirement of the customer. The operation is fully automatic with simultaneous plate pack opening & automatic cake discharge. This enables to achieve shorter cycle time with high availability. With easy inspection & maintenance, combining with advanced automation, Dewater SP filter presses complies to highest health & safety regulations.

Filtration Technologies

The Dewater SP model filter presses are flexible to be customised depending upon the requirement of the process & applications.

Applications which requires cake washing steps, cake drying with compressed air or high pressure cake squeezing the filter presses can be equipped with special membrane plates pack or mixed plate pack configurations with variable volume chambers.

Whereas for applications without above requirements the filter presses can be equipped with Chamber plate configurations.

Fast Filtration

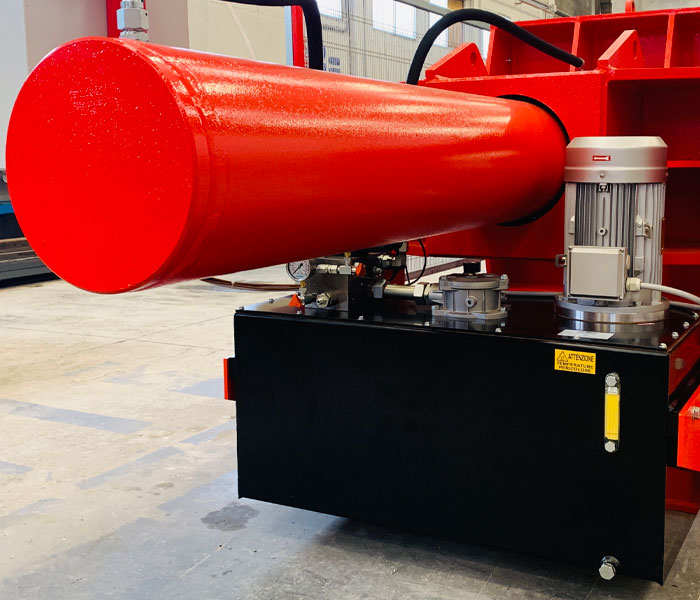

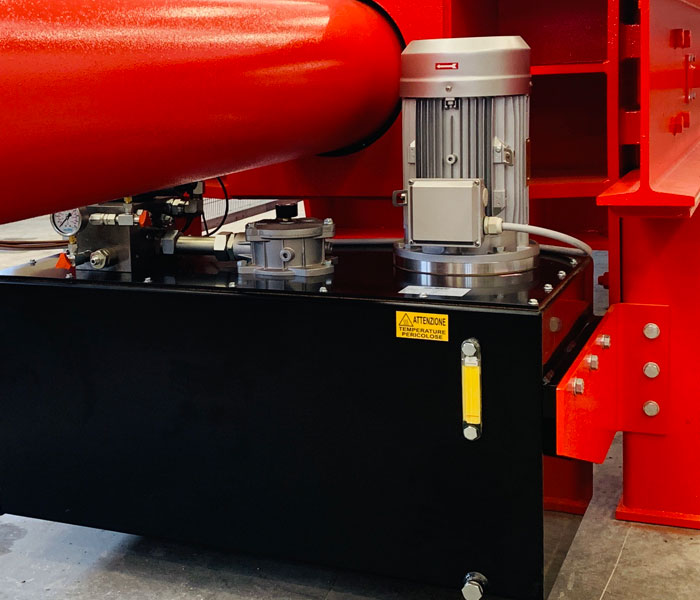

The strong structures combining with simultaneous opening & closing shortens the filter press cycle time. The fast & simultaneous opening is achieved with a hydraulic cylinder. The filter press plates are connected via links to the hydraulic head of the Filter Press.

The Fast filtration operation significantly increases the filter presses’ throughput production.

Dewater SP filter press models can open the plates pack in one, two, three or four steps according to the required productivity.

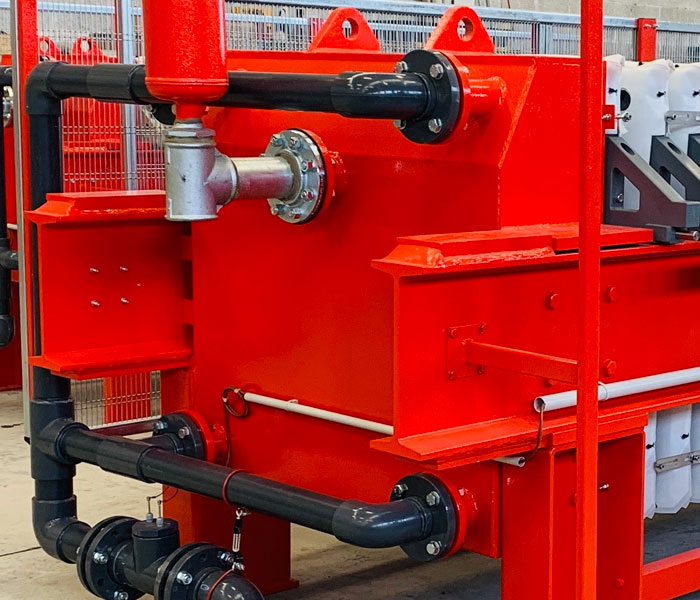

Automatic Cloth Washing

Dewater SP Filter Press are equipped with automatic cloth washing systems installed on the top of the filter press plate pack. It consists pipes equipped with nozzles.

In this operation, the filter cloths are simultaneously washed after every cycle. This guarantee a perfect sealing of the plate pack at every cycle. In addition it increases the life of cloths & plates.

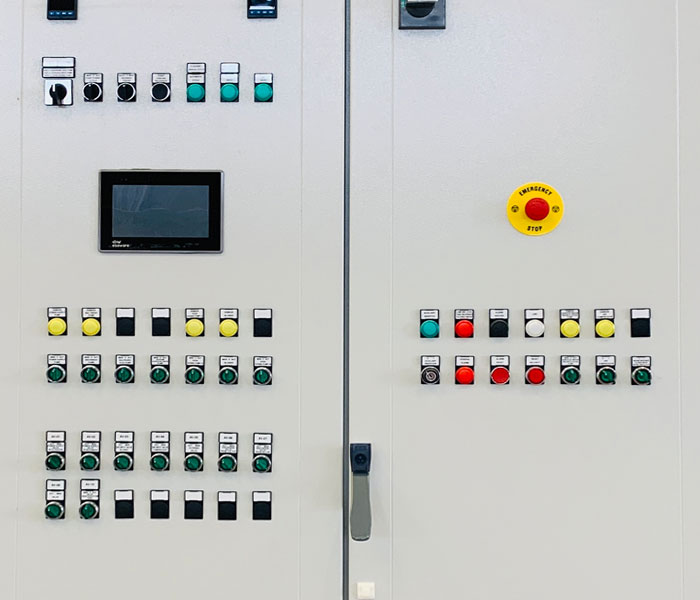

Advanced Automation

Dewater SP filter press uses advanced degree of automation with PLC complete with visual Human Machine Interface (HMI). This allows easy & efficient management of filter press operation, optimisation of filtration parameters according to the varying process requirements etc. Additionally it increases operational safety & assists in diagnosis and troubleshooting of faults.

Filter Press remote access can be optionally added to enhance the operational support upon request & to add preventive maintenance support.

Plate and Cloth Shaking

The pneumatic filter press plate & cloth shaking device ensures even the stickiest cake to be discharged automatically. Programmed to occur after the opening of the complete plate pack, this operation efficiently removes cake fragments & any parts of sticky cake from the cloths. This system allows the filter press to run automatically without any operator assistance.

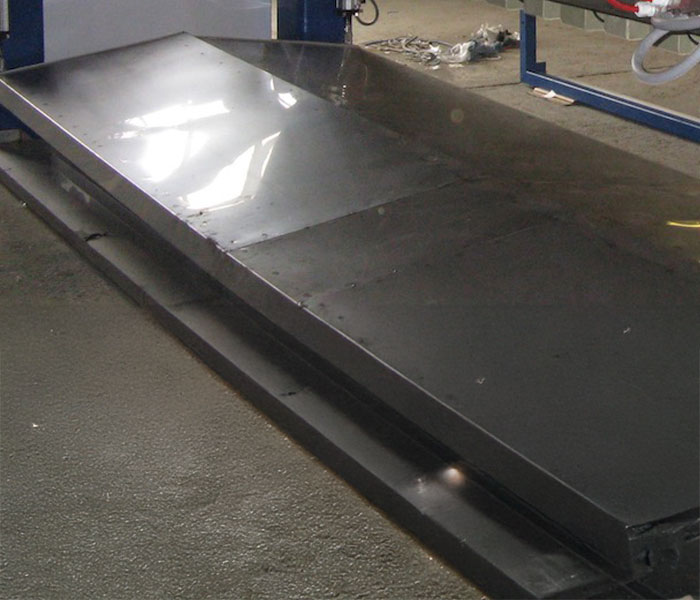

Drip Tray

Dewater SP Filter Presses can be equipped with the Drip Tray or even sometimes called as “bomb bay doors”. This is used to collect the washing water while the filter press is equipped with automatic cloth washing.

Safety

Dewater SP filter presses are designed keeping the basic safety principles of Safe Operation, Safe Inspection & Safe Maintenance. In addition to complying to the highest safety standards in practice, it increases the filter press availability resulting higher throughput.

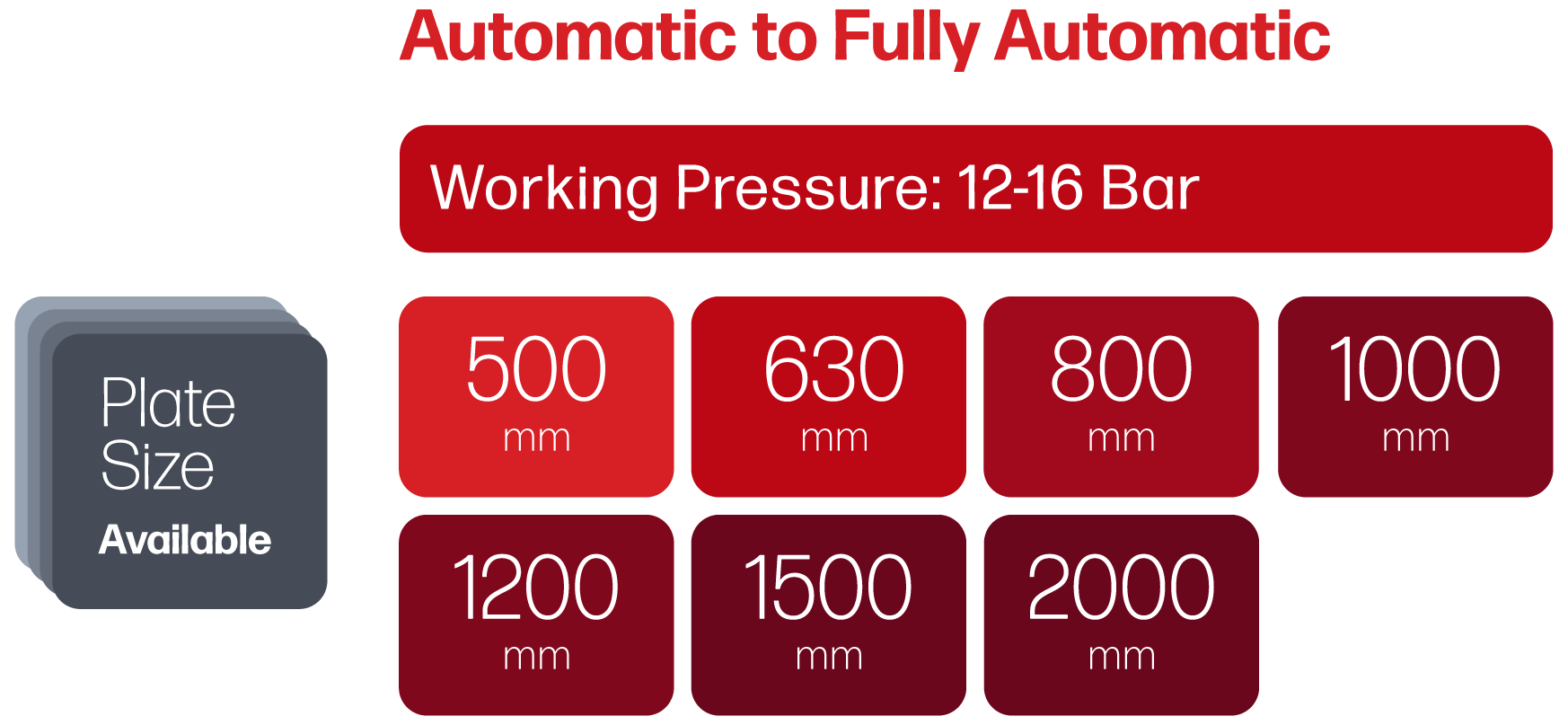

Technical Specifications

Medium to High Capacity

Check our other products

Dewater MAS HP 6×6

Dewater HP 4×4