Ore Concentrate filtration

Ore Concentrate filtration

What is the filtration or dewatering of ore concentrates?

After mine excavation, the mining process, forecasts to separate the valuable ore like iron ore, copper, zinc, molybdenum, coal concentrate etc.. from the undesired materials called tailings. This process is done in the ore concentrator plant or beneficiation plant. The main steps of the beneficiation process are crushing, milling, screening and the separation of the valuable ores like copper concentrate, zinc concentrate, iron ore concentrate, lead concentrate, fine coal or gold from the tailings. To make the separation of the valuable ores like copper concentrate, zinc concentrate, iron ore concentrate, lead concentrate, gold concentrate etc.. from the tailings, is used one of the following processes:

- flotation,

- leaching,

- bio leaching,

- or magnetic separation process like in the case of magnetite iron ore concentrate.

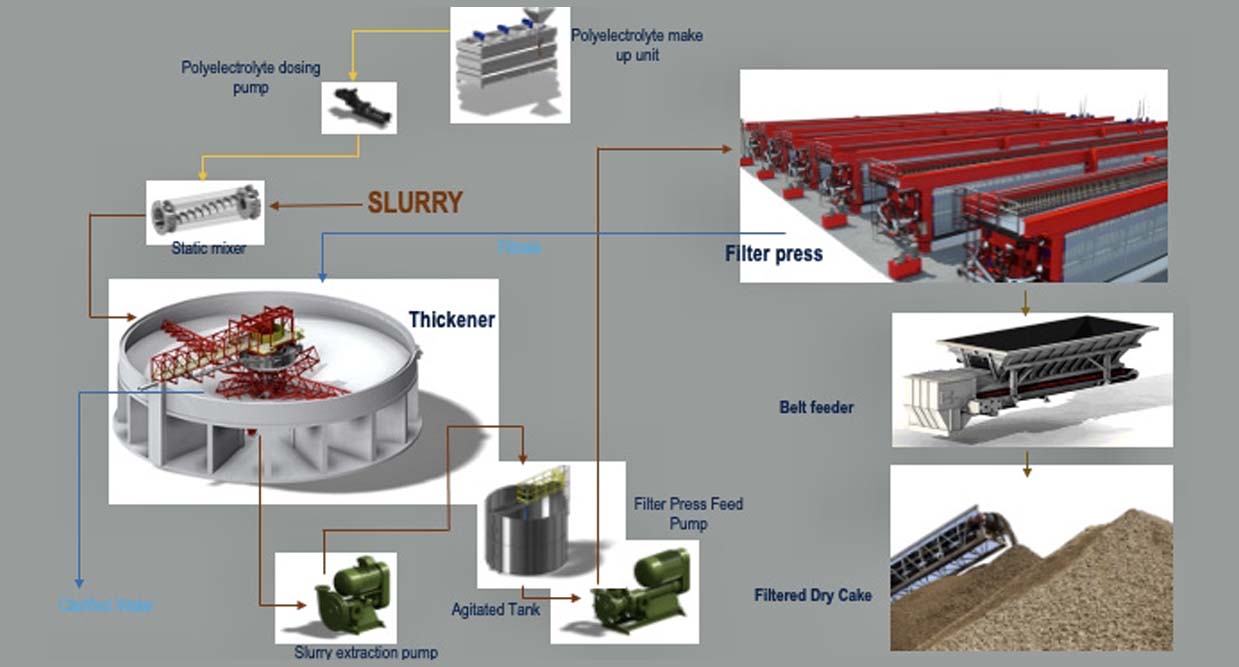

The separation or concentration process produce two streams of slurry: one is the slurry of the copper concentrate, zinc concentrate, iron ore concentrate, lead concentrate, fine coal or gold etc. The slurry of concentrate ores goes through thickening and then filtering and dewatering process before finally landing at the metallurgical plant. The filtration and the dewatering of ore concentrate is very important because a very dry ore concentrate is required in order to efficiently refine the ore in the metallurgical processes.

The other stream of undesired materials is called slurry tailings that will go to the tailings management process or tailings management plant.

In the past the common dewatering process of the slurries of ore concentrate used to make it in two steps: first the filtration of the thickened slurries by some vacuum technology like disc filter, drum filter, ceramic disc filter etc. And the second step is the drying step made by dryer. But today this old methodology is no longer efficient & cost effective.

Today the best available technology for the dewatering and filtration of the mineral concentres like copper concentrate, zinc concentrate, iron ore concentrate, lead concentrate, fine coal or gold is the membrane filter press technology.

The membrane filter press equipped with the cake drying system allows to make the filtration and drying of the ore concentrate in one single step. The membrane filter press thanks to its high pressure filtration and the cake drying system allows to reach a residual moisture lower than 7% even with fine concentrate ore, as it is required from most of the metallurgical process .

Of course the value of the required residual cake moisture in the dry filtered cake is linked to the different ores characteristics. Like copper concentrate, zinc concentrate, iron ore concentrate, lead concentrate, fine coal or gold have different level of required residual moisture after membrane filter press dewatering process.

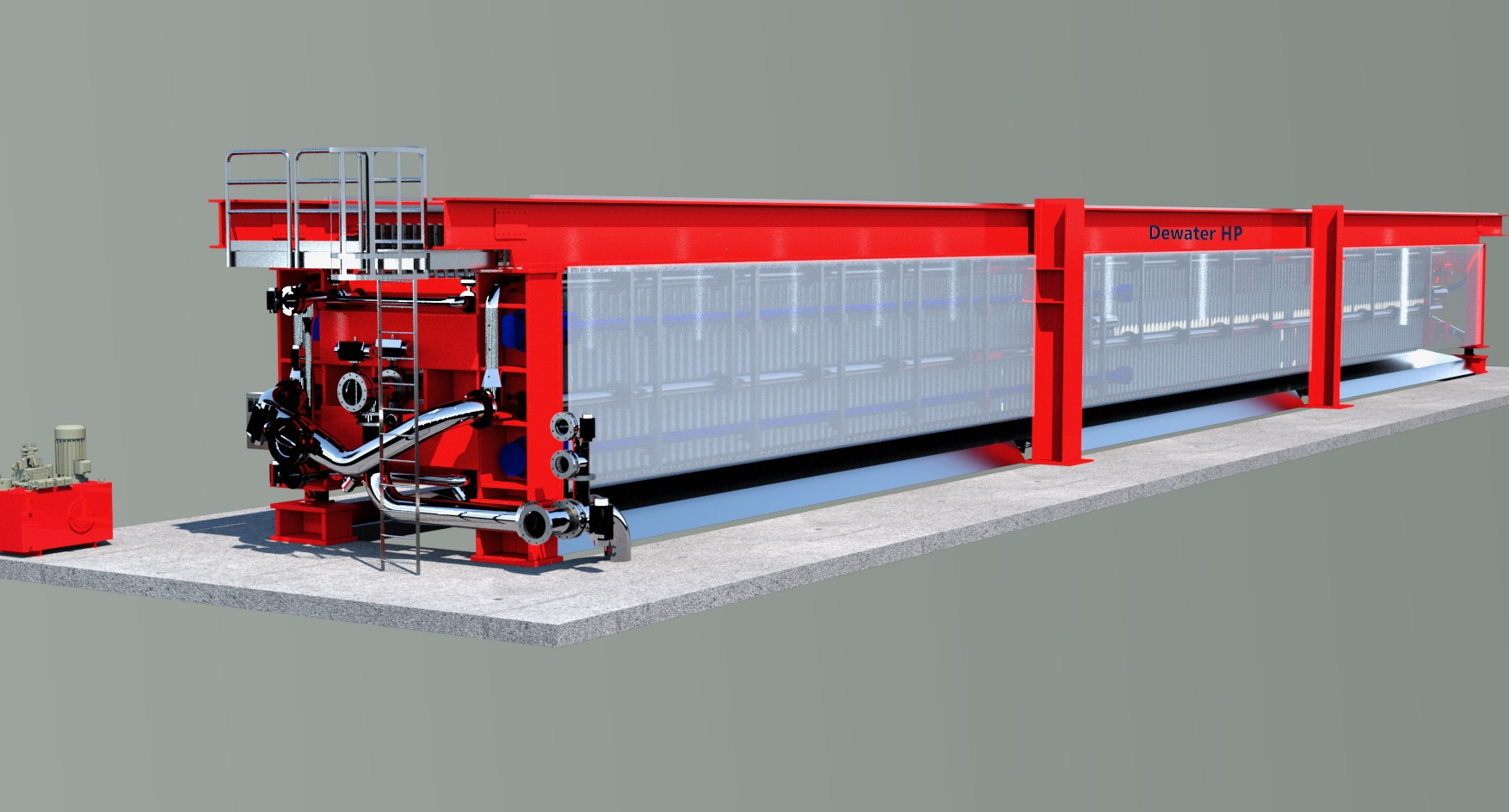

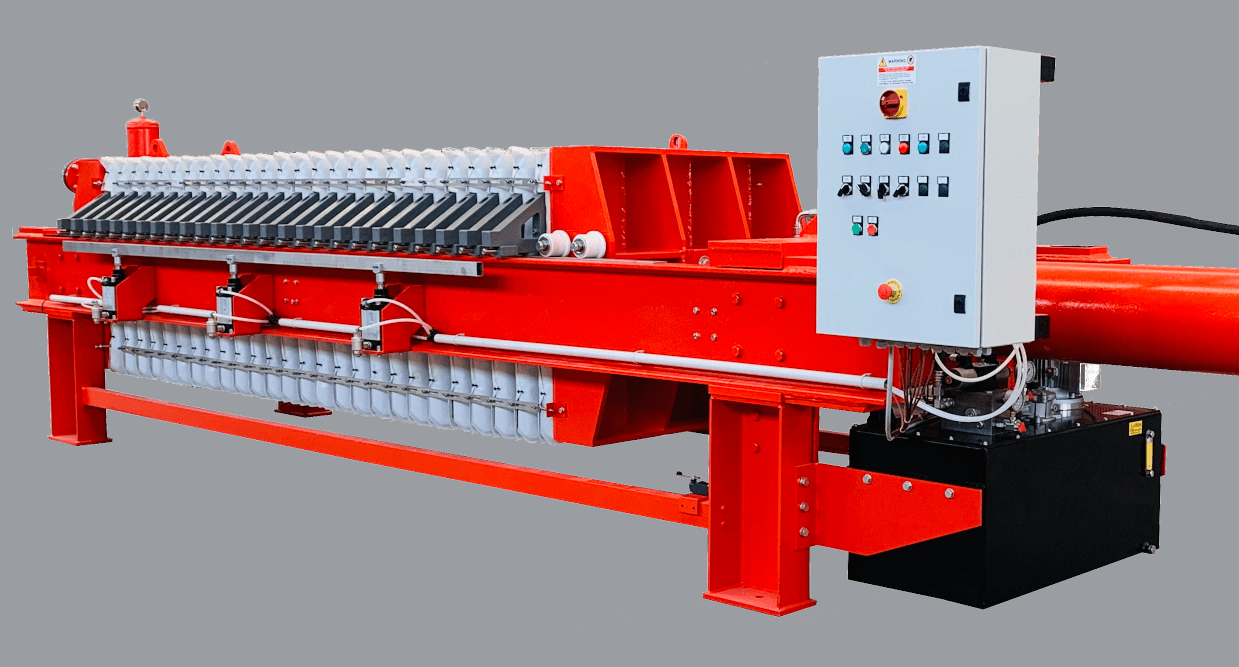

For the ore concentrate filtration Dewater Filter Press has developed the Dewater HP membrane filter press. It is a very fast and fully automatic filter press able to dewater a medium, high or very high volume of mineral concentrates like in the case of copper concentrate, iron ore concentrate, Zinc concentrate, fine coal etc. Instead for the filtration of medium to small capacity ore concentrates the Dewater SP membrane filter press can be used like in the case of lead concentrate, molybdenum concentrate etc.